Slitting involves unwinding a wide master coil and precisely cutting it longitudinally into multiple narrower coils (or “mults”) of specified widths. This process is essential for supplying materials in custom widths required by downstream manufacturing processes, offering greater flexibility and reducing material waste.

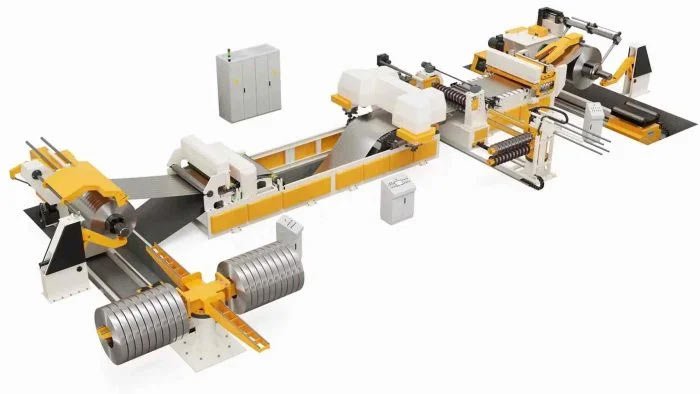

The wide master coil is loaded onto an uncoiler.

The material passes through a slitting head equipped with precision rotary knives (circular blades) set to the desired widths.

Individual slit strips are then precisely recoiled onto separate mandrels, maintaining consistent tension to ensure tight, uniform coils.

Our slitting lines are designed to provide clean, burr-free edges.

Strips for Stamping, Tubing, Profiles, Exhaust Systems.

Narrow Strips for Appliance Frames, Internal Mechanisms.

Metal Studs, Roof Flashing, Profiles for Windows and Doors.

Components for Electrical Conduit, HVAC Ductwork, Fasteners, Precision Tubing.

Strips used in Cable Armouring and Protection.